Assembly and Testing

What we can do for you

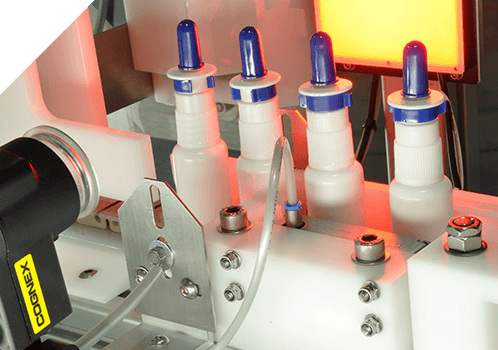

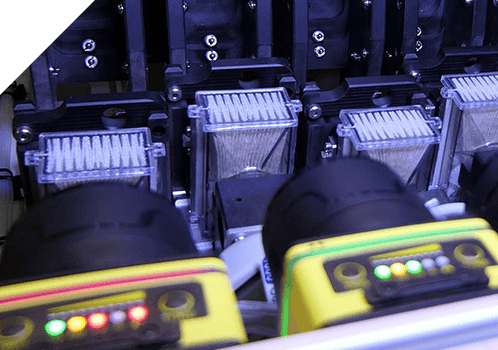

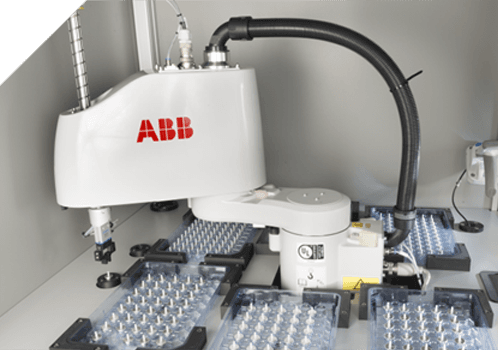

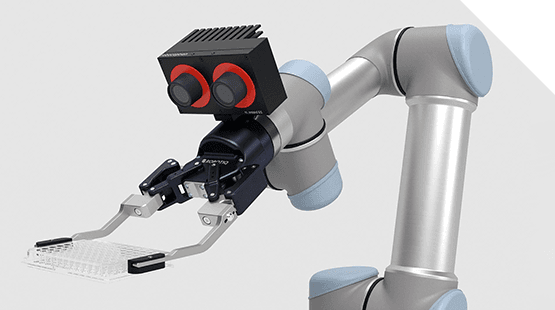

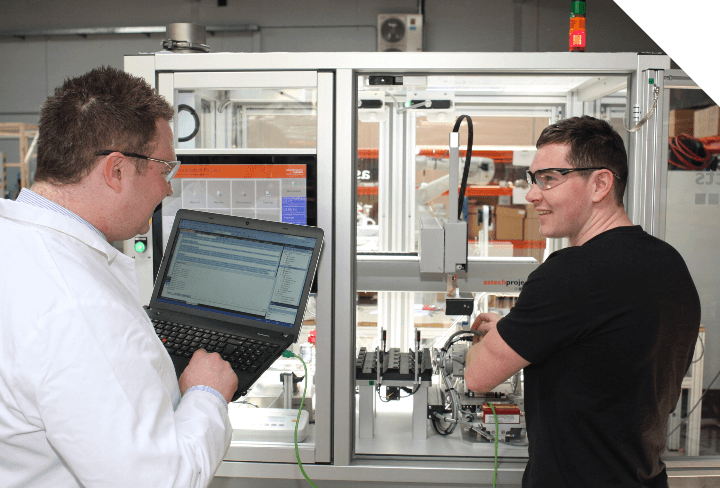

We design and build automated and semi-automated workstations for product assembly and testing involving small components, delicate materials, irregular shapes, hazardous materials, and controlled substances. We can provide automated systems that are suitably scaled for the appropriate stage in your product’s development lifecycle. Astech utilize the latest robotic and vision technology that can handle every step of automated testing in production, from manipulating fragile laboratory items and PCBs to precisely orientating complex aero engine parts. With Astech’s extensive experience with medical device testing we understand clinical parameters, device safety and efficacy needs, not just in the pharmaceutical product but in the physical device that delivers it. Consistency and accuracy are critical in advanced manufacturing. Batch failure at any point in the process results in wasted time and materials, eroding precious margin. Maintaining consistency and product quality is paramount for product safety and brand reputation. A well-designed automated system will incorporate in-process checks and controls, identifying batch quality issues, resulting in fewer rejected goods at final inspection.

Features

Your automated system might include any of the following:

Machine Vision inspection

Weight checking pre/post filling or coating

Cycle counters and rejected parts counting

Laser alignment

Network connections for data storage

Electrical circuit testing

Functional testing

Orientation check to ensure correct placement of components

Safety and sensing such as light shields, pressure sensors and monitoring

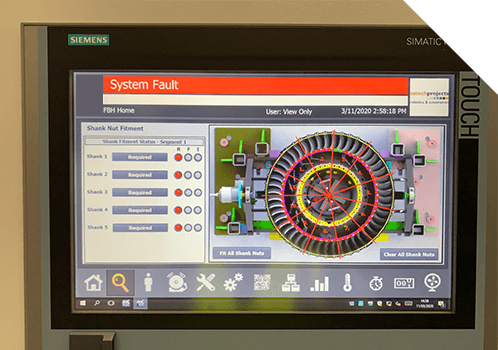

HMI touchscreen monitors for easy process side control

Why should you automate?

Items of a complex or critical nature generally have to meet a multitude of regulatory requirements. Through experience, Astech understand that automation of manufacturing and testing processes within highly regulated sectors such as pharmaceutical, medical device assembly and civil aerospace not only has to satisfy the efficiency, safety and product quality demands of our customers but also comply with regulatory and international quality standards. Consider a semi or fully automated assembly solution if you:

Have a challenging operating environment

Want to cut down on waste

Need to increase production speed

Need to ensure repeatability

Need to accelerate product development cycles

Have had issues with human error: manual measurements and mishandling

Have a product that is sensitive to temperature, dust, humidity, vibrations, etc.

Software

Our software can provide quick and accurate transfer of results, summary reports on performance, reject rates and more. Tracking and recording of batch or individual product numbers, raw material weights, operator ID, conditions, and tolerances providing a full audit trail. Data can be integrated with other Management Information Systems to provide actionable insights.

Bespoke solutions

"Astech can guide you through identifying and designing a semi or fully automated solution that fits your needs. We can provide flexible and scalable systems that will allow your assembly and testing process to expand and adapt as your product volumes increase. We can also provide full maintenance and support from our dedicated REACTS® Service & Support team, giving you peace of mind when it comes to your business-critical processes. For more than 25 years we have worked with companies large and small, to successfully integrate custom automation systems with all types and brands of equipment and software. Astech ensure our automated systems adhere to the relevant industry regulations and guidelines, such as Good Automated Manufacturing Practice (GAMP), FDA CFR and ISO, helping you meet critical industry standards."

Discover more about Astech

Explore our products, applications and REACTS support and maintenance service

Get in contact with us

![[object Object]](/_next/image?url=https%3A%2F%2Fcdn.sanity.io%2Fimages%2Fpk0repno%2Fproduction%2Fdbf3a5f83007da9e59edb68fb82b530f003f1265-376x220.png&w=828&q=75)

![[object Object]](/_next/image?url=https%3A%2F%2Fcdn.sanity.io%2Fimages%2Fpk0repno%2Fproduction%2F1129b34fb570be1e0a58285546ffbcba387248c2-838x342.png&w=1920&q=75)